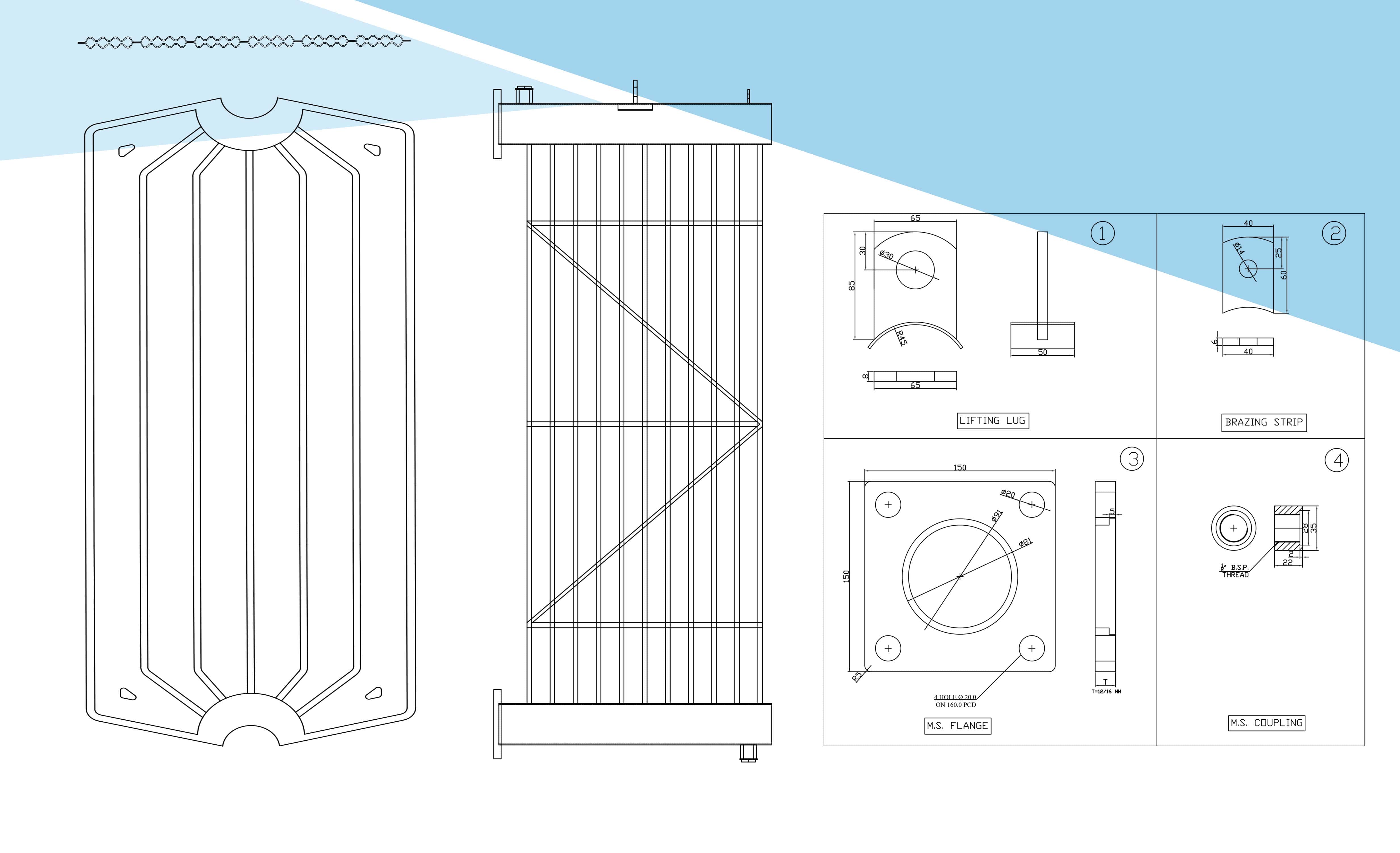

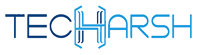

Technical Specifications of Transformer radiators:

We have facility of making Radiators of 300mm and 520mm both 1.00mm & 1.2mm with 24 flutes design which conforms to IEEMA 9:1990 & DIN 42559 Standards. Our Facility can make center to center(C/C) from 600mm to 4000mm with No. of fins ranging upto 40 fins with in-between distance (Pitch) of 45,50,60,65,75 as per customer requirement.

PAINTING OF RADIATORS:

INTERNAL: All the radiators are cleaned with air and then flushed with Insulating varnish as per IS 10026 which is compatible with most of the transformer oil. Also we provide flushing of Transformer Oil if required by the customer.

EXTERNAL: Firstly the radiators undergo degreasing process to remove all the oil, grease or any contamination stick to it and then the radiators are shot blasted with shots to achieve profile which conforms SA2-1/2.

The radiators are flow coated as per customer requirement with Zinc Primer, Zinc Rich Primer, MIO, Epoxt Paint, PU Paint of any shade according to different Painting schemes such as PS-3, PS-4, PS-5, Ps-8.

TESTING of Radiators:

All the radiators are pressure tested with air @2kg/cm2 under water for 30 mins. For painting different tests such as Surface profile guage for roughness of surface, DFT meter for coating thickness, Adhesion test, Pull of Test, dust adhesion tape, vacuum test are performed with trained Quality Engineer to ensure the accuracy and surety of each radiator.